110 YEARS OF LINDEMANN – 100 YEARS METAL RECYCLING SOLUTIONS

History

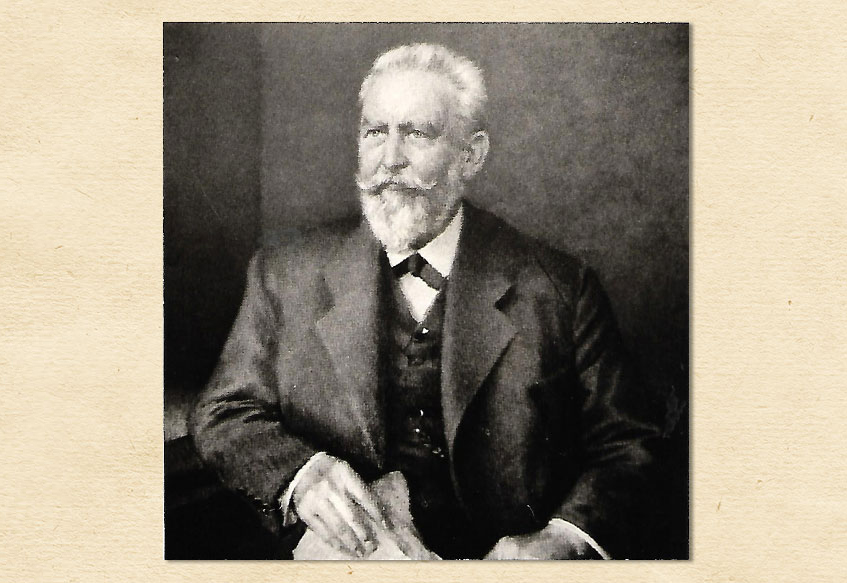

Waldemar Lindemann founded his own trading company of the same name in Düsseldorf on October 1st, 1913, at the age of 27. The idea struck him during a traineeship at an Antwerp export house, where he was responsible for logistics. He noticed that the more bulky and voluminous the goods, such as cotton, sisal or hemp, were, the more expensive it was to transport them. Waldemar conducted a market analysis and discovered that there were hardly any machines that could compact these goods and reduce their volume in a way that was economically attractive. He seized this opportunity and launched his own business designing and producing baling presses. His father Robert, who was already a renowned hydraulic engineer at the end of the 18th century, was a great help to him in this venture.

-

How the LINDEMANN story began

All Lindemann machines were produced exclusively in Osnabrück between 1913 and 1931.

The founding years

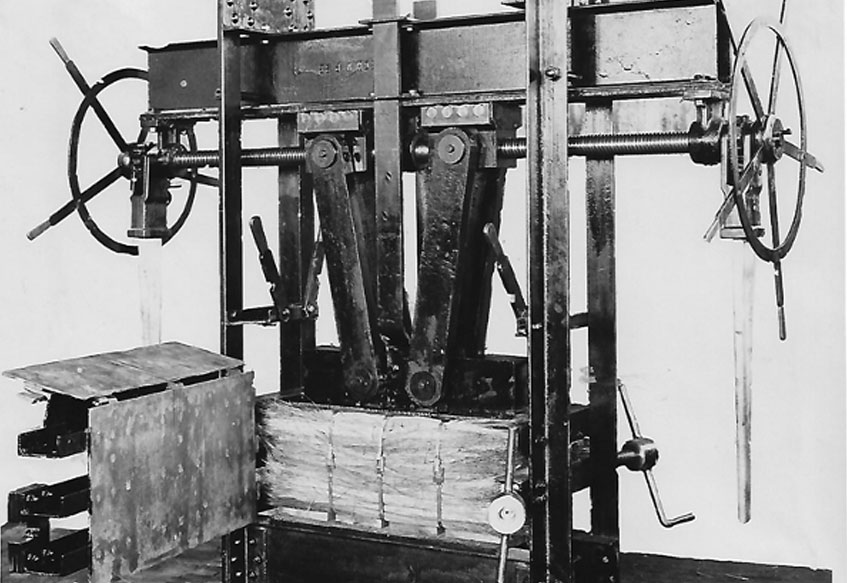

Waldemar's father Robert Lindemann was granted permission to build a mechanical workshop as far back as 1893. The apple did not fall far from the tree: For his Lindemann company, Waldemar worked together with his father to develop various baling presses for paper and cardboard, both mechanically and electrically driven, from 1913 onwards. In 1919, Waldemar began the development and construction of baling presses independently of his father.

-

Industrialization demands metal recycling

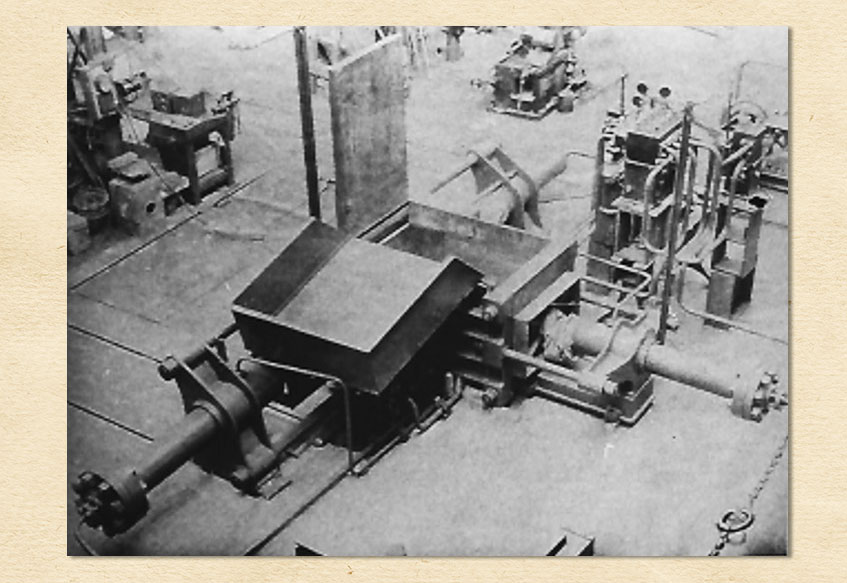

Hydraulic scrap baling press "Asper"

The world’s first metal recycling machine entered the market

Waldemar tried to gain a foothold in the scrap processing industry a few years later. His father's hydraulics expertise was invaluable in this respect. This expertise was successfully put to use when the world's first hydraulically operated scrap press was developed. Lindemann delivered it to a customer in England in 1923, five years following the death of Robert Lindemann. It helped the company make its international breakthrough. With the rise of industrialization, the volume of scrap metal that needed to be packaged for transport to the smelting furnace also increased. This was followed by the first mobile scrap press in 1926 and the first end press. Lindemann began building its first large machines at the end of 1928. The "Asper" hydraulic scrap press already measured six meters at the time.

-

Leading the Metal Recycling Industry

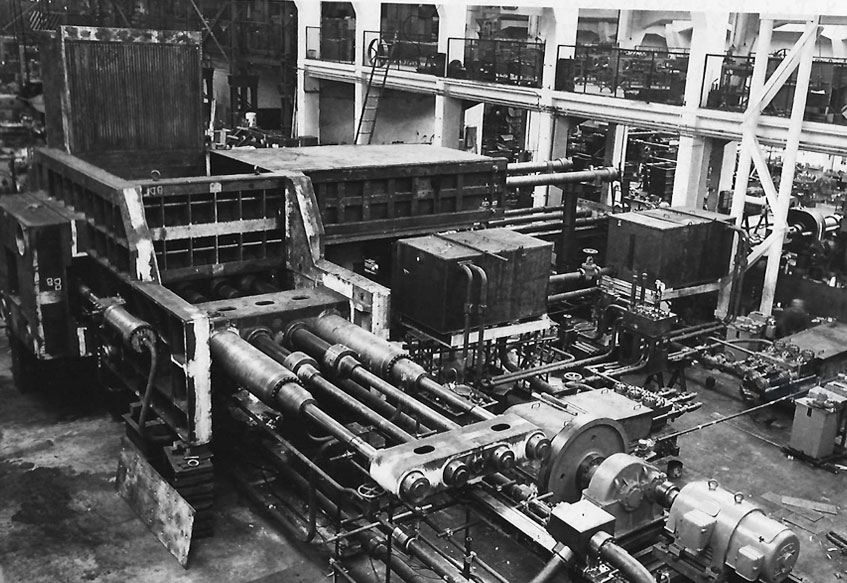

Assembly hall scrap press

LINDEMANN represented on each Scrap Yard Europe-wide

LINDEMANN machines could be found in all the scrap yards of Europe in the 1930s. Among other things, Lindemann built and supplied "chip mills" as well as various sized scrap baling presses - for scrap yards as well as for steel mills or small, metal processing companies. These were used, for example, for briquetting sheet metal strips and metal chips. Furthermore, the first scrap shears came into the market. Alligator shears, as they were called, constituted the first model of shears, of which 1,200 were sold worldwide over the next 30 years. 1931 saw Lindemann move production from Osnabrück to Düsseldorf to the premises of Oeking AG, on Erkrather Strasse.

-

After the Second World War

Aerial view of factory buildings

Old drawings made a new start possible

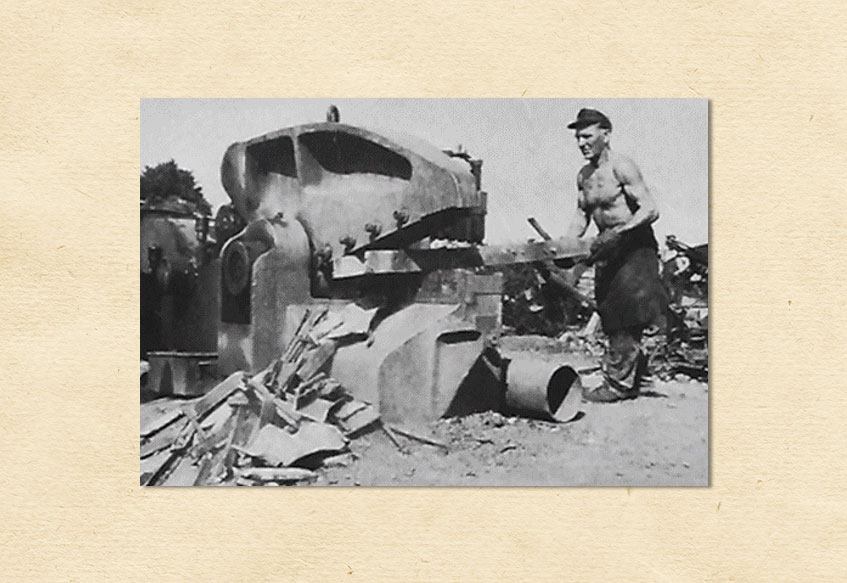

The time shortly before and particularly during World War II was traumatic, as it had been for many manufacturing companies in Germany. The company in the form that Waldemar founded it no longer existed. The LINDEMANN factory found itself being misused for the production of munitions. It was closed by the Allies at the beginning of 1946. It was initially supposed to be dismantled, a decision that was abandoned. Instead, all construction drawings were confiscated.

Thankfully, Waldemar's brother Kurt Lindemann's company in Cologne still had drawings that made a new start possible. They founded the Gesellschaft zur Konstruktion Bau Hydraulischer Pressenanlage Lindemann mbH between 1947 and 1948, which was renamed Lindemann Pressenbau GmbH Köln in 1949. -

LINDEMANN expand to the USA

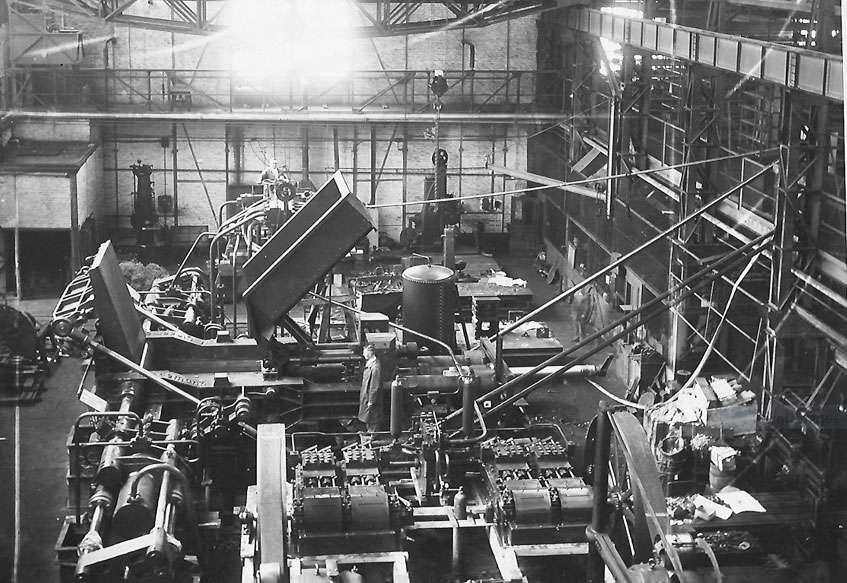

Hydraulic scrap shear for Luria Brothers, USA

Pioneering cooperation with Lake Erie

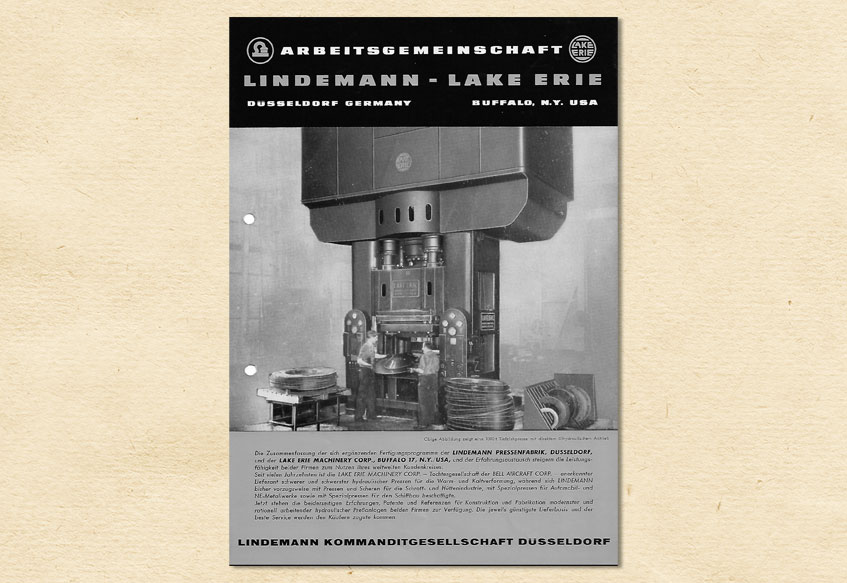

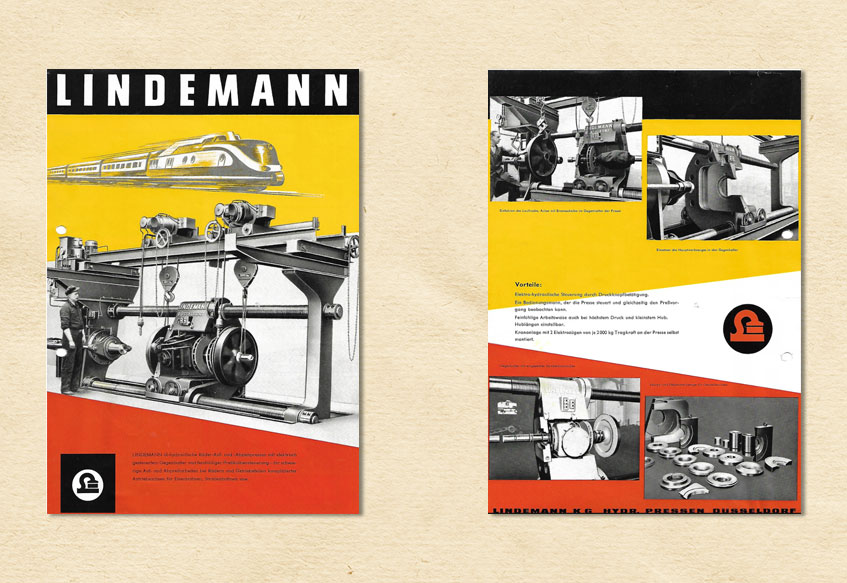

Operations finally returned to Düsseldorf in 1952. Waldemar once again changed the company's name, to Lindemann Maschinenfabrik GmbH Düsseldorf and, together with his daughter Ingelore, cranked up the business in earnest. The demand for large scrap baling presses increased tremendously after World War II. Waldemar founded Lindemann KG seven years later, starting in 1959 as a pure sales company, paving the way for international trade, including in the USA. Their pioneering cooperation with Lake Erie, a hydraulics company based in Buffalo, was a milestone at the time. Meanwhile, the great era of scrap shears was taking off at the end of the 1950s. In 1958, the world's first hydraulically operated scrap shear, with a shear force of 1,200 t, was delivered to Luria Brothers, the largest scrap company in the USA at the time. Many other special shears followed.

-

The great age of scrap shears

Prince Charles examines a model in the UK representation

LINDEMANN presence in more than 50 countries worldwide

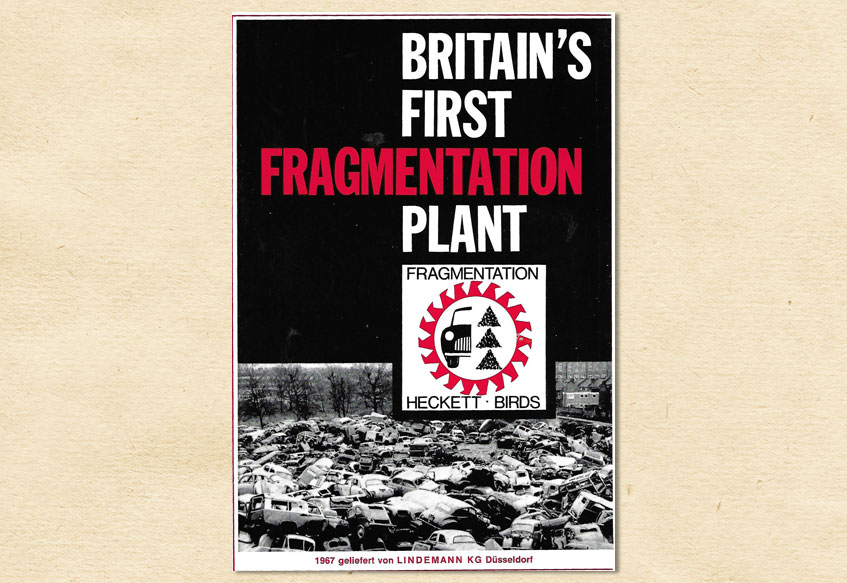

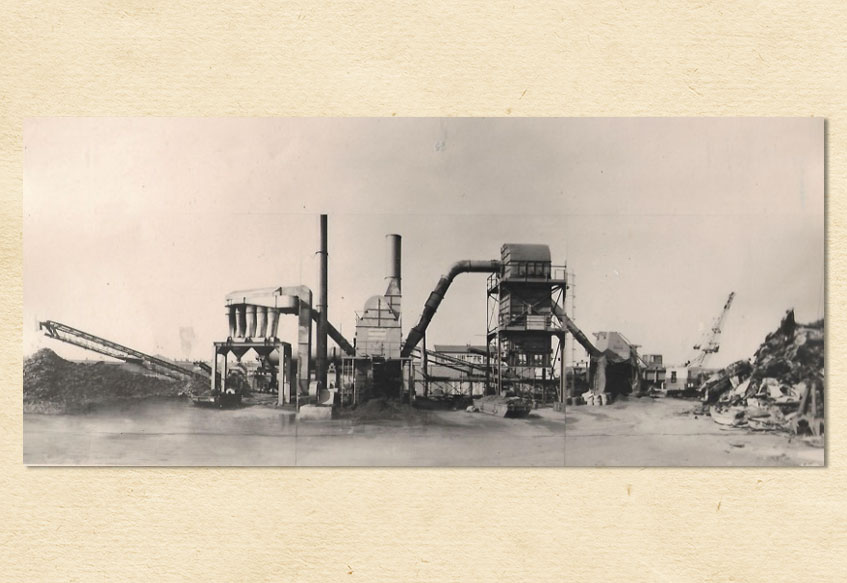

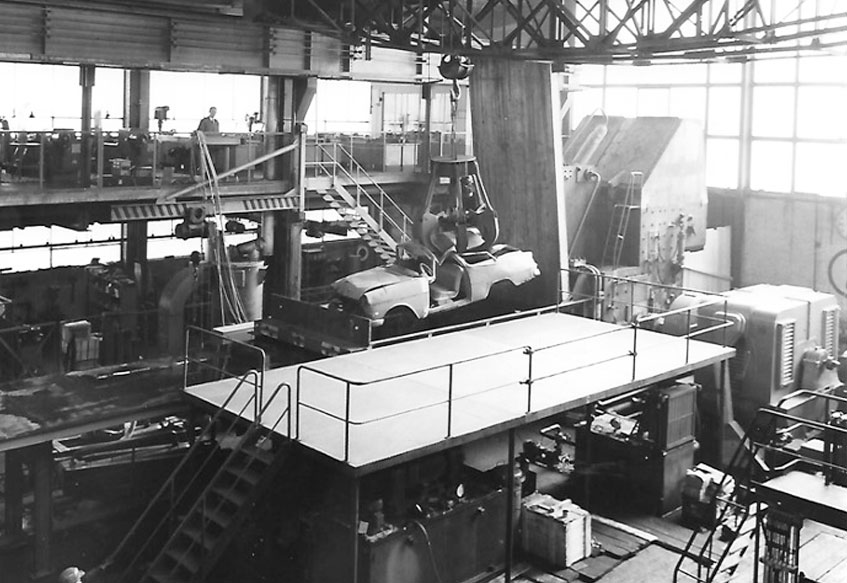

The scrap shear business was flourishing in the 1960s. During the same period, LINDEMANN was working on the first shredder tests for crushing metal scrap, at first with a hammer mill, then later with a newly designed automotive shredder. The success was clear to see: Scrap metal processors practically snatched the first automotive shredders out of LINDEMANN's hands. Waldemar Lindemann passed away in 1964 and his daughter Ingelore became the sole owner. As of this date, the operational business was managed by a management team that included Ingelore's husband, General Consul Schoeme. LINDEMANN purchased the Düsseldorf-based company Hartung Kuhn & Co in 1965, boosting the company's own production capacity in the process. The company continued to grow steadily. LINDEMANN already employed 1,000 people by the mid-1960s and had a presence in more than 50 countries worldwide. England's first large-scale shredder lines were installed by LINDEMANN in 1967.

-

LINDEMANN production for Deutsche Bahn

Demand for pressing metal scrap increased

The scrap presses grew larger and more powerful - the largest hydraulic press of the time was already powered at 750 hp. The demand for pressing new sheet metal scrap increased, especially in automotive factories. LINDEMANN further developed the wheel mounting and dismounting presses for Deutsche Bahn and DÜWAG in Düsseldorf. The shredder business boomed during the same period.

-

Shredder business grows

Shredder with rotor lift and driving power 750 kW

LINDEMANN extended to further countries

The license agreement with Newell expired in the 1980s, and from that point on LINDEMANN marketed its shredders without a license, continuously developing them, and significantly expanding its international business. Besides the USA, LINDEMANN established additional sites in Switzerland, England, Spain, Brazil, France, and Japan.

-

LINDEMANN was sold to Svedala Industries

New opportunities opened up in the USA

LINDEMANN was sold for the first time to Svedala Industries AB from Sweden in 1997. The company name was changed to Svedala Lindemann GmbH. This gave the company financial reinforcement and helped it to secure and further expand its market position. New opportunities opened up in the USA during the same period: Svedala Universal Engineering from Cedar Rapids, which manufactured the Hammersmill shredders, was already part of the Svedala Group, something that was an advantage for the future shredder business. Svedala also contributed valuable expertise in wear casting technology thanks to the construction of mineral processing machines.

-

From Metso back to LINDEMANN

...21st century is LINDEMANNs most successful business period

Just four years after Svedala Industries bought Lindemann, Svedala itself, including Svedala Lindemann GmbH, was taken over by Metso in 2001 and continued as Metso Lindemann GmbH. Metso initially consolidated Svedala's and Metso's existing metal and recyclables processing segments into Metso Minerals. The business was later spun off into a newly formed division as Metso Recycling. Metso added San Antonio-based Texas Shredder to its portfolio in 2005, thereby expanding its shredding expertise.

There was an enormous demand for scrap processing facilities especially between the years 2004 to 2010. It was the most successful business period in the "Lindemann history" so far, next to the formative and strong 1960s.

The pre-shredder was launched in 2013 and installed for the first time in France as a shredding element upstream of the shredding process to reduce deflagrations and wear in the expensive main shredder. Today's further enhanced EtaRip is regarded as the most sought-after pre-shredder in the market. The portfolio was expanded to include the N-series in 2016 - for processing smaller and medium scrap volumes. The first delivery was made to the USA in 2017.

LINDEMANN returned to being LINDEMANN in 2022. Backed by the investor Mimir, the core values of the founder Waldemar Lindemann “Quality, Performance, and Innovation” will once again be brought into sharper focus and further developed. In doing so, the company is concentrating on relevant topics such as digitalization and sustainability, optimizing internal structures and work processes, and investing in new personnel. The growth curve continues to rise more steeply than expected. -

Happy Birthday

LINDEMANN celebrates double anniversary: its establishment and its first steps into the metal recycling industry

January 12, 2023: LINDEMANN started into its centennial with a stunning Metal Recycling Day, held at its production partner Severt, with special guest Tom Bird, President of BIR. Two hundred invited guests from all over the world as well as international trade media press came to see the flagship machines EtaCut II and EtaPress, joined a factory tour, listened to interesting speeches from Daniela Entzian (BDSV), Philippe Russo (ArcelorMittal), Dr. Walter Hilgert (R&R Beth), Klemens Häusler (Software Management), Karl Hoffmann (STEINERT), Markus Döbbelt (Spaleck), and enjoyed the evening with a gorgeous dinner.

-

1913

1913How the LINDEMANN story began

The founding years

Waldemar's father Robert Lindemann was granted permission to build a mechanical workshop as far back as 1893. The apple did not fall far from the tree: For his Lindemann company, Waldemar worked together with his father to develop various baling presses for paper and cardboard, both mechanically and electrically driven, from 1913 onwards. In 1919, Waldemar began the development and construction of baling presses independently of his father.

-

1920

1920Industrialization demands metal recycling

The world’s first metal recycling machine entered the market

Waldemar tried to gain a foothold in the scrap processing industry a few years later. His father's hydraulics expertise was invaluable in this respect. This expertise was successfully put to use when the world's first hydraulically operated scrap press was developed. Lindemann delivered it to a customer in England in 1923, five years following the death of Robert Lindemann. It helped the company make its international breakthrough. With the rise of industrialization, the volume of scrap metal that needed to be packaged for transport to the smelting furnace also increased. This was followed by the first mobile scrap press in 1926 and the first end press. Lindemann began building its first large machines at the end of 1928. The "Asper" hydraulic scrap press already measured six meters at the time.

-

1930

1930Leading the Metal Recycling Industry

LINDEMANN represented on each Scrap Yard Europe-wideLINDEMANN machines could be found in all the scrap yards of Europe in the 1930s.

Among other things, Lindemann built and supplied "chip mills" as well as various sized scrap baling presses - for scrap yards as well as for steel mills or small, metal processing companies. These were used, for example, for briquetting sheet metal strips and metal chips. Furthermore, the first scrap shears came into the market. Alligator shears, as they were called, constituted the first model of shears, of which 1,200 were sold worldwide over the next 30 years. 1931 saw Lindemann move production from Osnabrück to Düsseldorf to the premises of Oeking AG, on Erkrather Strasse.

-

1940

1940After the Second World War

Old drawings made a new start possible

The time shortly before and particularly during World War II was traumatic, as it had been for many manufacturing companies in Germany. The company in the form that Waldemar founded it no longer existed. The LINDEMANN factory found itself being misused for the production of munitions. It was closed by the Allies at the beginning of 1946. It was initially supposed to be dismantled, a decision that was abandoned. Instead, all construction drawings were confiscated. Thankfully, Waldemar's brother Kurt Lindemann's company in Cologne still had drawings that made a new start possible. They founded the Gesellschaft zur Konstruktion Bau Hydraulischer Pressenanlage Lindemann mbH between 1947 and 1948, which was renamed Lindemann Pressenbau GmbH Köln in 1949.

-

1950

1950LINDEMANN expand to the USA

Pioneering cooperation with Lake Erie

Operations finally returned to Düsseldorf in 1952. Waldemar once again changed the company's name, to Lindemann Maschinenfabrik GmbH Düsseldorf and, together with his daughter Ingelore, cranked up the business in earnest. The demand for large scrap baling presses increased tremendously after World War II. Waldemar founded Lindemann KG seven years later, starting in 1959 as a pure sales company, paving the way for international trade, including in the USA. Their pioneering cooperation with Lake Erie, a hydraulics company based in Buffalo, was a milestone at the time. Meanwhile, the great era of scrap shears was taking off at the end of the 1950s. In 1958, the world's first hydraulically operated scrap shear, with a shear force of 1,200 t, was delivered to Luria Brothers, the largest scrap company in the USA at the time. Many other special shears followed.

-

1960

1960The great age of scrap shears

LINDEMANN presence in more than 50 countries worldwide

The scrap shear business was flourishing in the 1960s. During the same period, LINDEMANN was working on the first shredder tests for crushing metal scrap, at first with a hammer mill, then later with a newly designed automotive shredder. The success was clear to see: Scrap metal processors practically snatched the first automotive shredders out of LINDEMANN's hands. Waldemar Lindemann passed away in 1964 and his daughter Ingelore became the sole owner. As of this date, the operational business was managed by a management team that included Ingelore's husband, General Consul Schoeme. LINDEMANN purchased the Düsseldorf-based company Hartung Kuhn & Co in 1965, boosting the company's own production capacity in the process. The company continued to grow steadily. LINDEMANN already employed 1,000 people by the mid-1960s and had a presence in more than 50 countries worldwide. England's first large-scale shredder lines were installed by LINDEMANN in 1967.

-

1970

1970LINDEMANN production for Deutsche Bahn

Demand for pressing metal scrap increased

The scrap presses grew larger and more powerful - the largest hydraulic press of the time was already powered at 750 hp. The demand for pressing new sheet metal scrap increased, especially in automotive factories. LINDEMANN further developed the wheel mounting and dismounting presses for Deutsche Bahn and DÜWAG in Düsseldorf. The shredder business boomed during the same period.

-

1980

1980Shredder business grows

LINDEMANN extended to further countries

The license agreement with Newell expired in the 1980s, and from that point on LINDEMANN marketed its shredders without a license, continuously developing them, and significantly expanding its international business. Besides the USA, LINDEMANN established additional sites in Switzerland, England, Spain, Brazil, France, and Japan.

-

1990

1990LINDEMANN was sold to Svedala Industries

New opportunities opened up in the USA

LINDEMANN was sold for the first time to Svedala Industries AB from Sweden in 1997. The company name was changed to Svedala Lindemann GmbH. This gave the company financial reinforcement and helped it to secure and further expand its market position. New opportunities opened up in the USA during the same period: Svedala Universal Engineering from Cedar Rapids, which manufactured the Hammersmill shredders, was already part of the Svedala Group, something that was an advantage for the future shredder business. Svedala also contributed valuable expertise in wear casting technology thanks to the construpction of mineral processing machines.

-

2000

2000From Metso back to LINDEMANN

21st century is LINDEMANNs most successful business period

Just four years after Svedala Industries bought Lindemann, Svedala itself, including Svedala Lindemann GmbH, was taken over by Metso in 2001 and continued as Metso Lindemann GmbH. Metso initially consolidated Svedala's and Metso's existing metal and recyclables processing segments into Metso Minerals. The business was later spun off into a newly formed division as Metso Recycling. Metso added San Antonio-based Texas Shredder to its portfolio in 2005, thereby expanding its shredding expertise. There was an enormous demand for scrap processing facilities especially between the years 2004 to 2010. It was the most successful business period in the "Lindemann history" so far, next to the formative and strong 1960s. The pre-shredder was launched in 2013 and installed for the first time in France as a shredding element upstream of the shredding process to reduce deflagrations and wear in the expensive main shredder. Today's further enhanced EtaRip is regarded as the most sought-after pre-shredder in the market. The portfolio was expanded to include the N-series in 2016 - for processing smaller and medium scrap volumes. The first delivery was made to the USA in 2017. LINDEMANN returned to being LINDEMANN in 2022. Backed by the investor Mimir, the core values of the founder Waldemar Lindemann “Quality, Performance, and Innovation” will once again be brought into sharper focus and further developed. In doing so, the company is concentrating on relevant topics such as digitalization and sustainability, optimizing internal structures and work processes, and investing in new personnel. The growth curve continues to rise more steeply than expected.

-

2023

2023Happy Birthday

LINDEMANN celebrates double anniversary: its establishment and its first steps into the metal recycling industry

January 12, 2023: LINDEMANN started into its centennial with a stunning Metal Recycling Day, held at its production partner Severt, with special guest Tom Bird, President of BIR. Two hundred invited guests from all over the world as well as international trade media press came to see the flagship machines EtaCut II and EtaPress, joined a factory tour, listened to interesting speeches from Daniela Entzian (BDSV), Philippe Russo (ArcelorMittal), Dr. Walter Hilgert (R&R Beth), Klemens Häusler (Software Management), Karl Hoffmann (STEINERT), Markus Döbbelt (Spaleck), and enjoyed the evening with a gorgeous dinner.