Metal Balers

Scrap metal balers designed for scrap yards and processing steel, aluminum, copper and other metals

The ever-changing demands of the scrap processing industry require a bigger choice of solutions capable of meeting specific capacity needs. LINDEMANN's wide range of scrap metal balers is designed for scrap yards and various industrial applications processing steel, aluminum, copper and other metals in variable shapes and sizes.

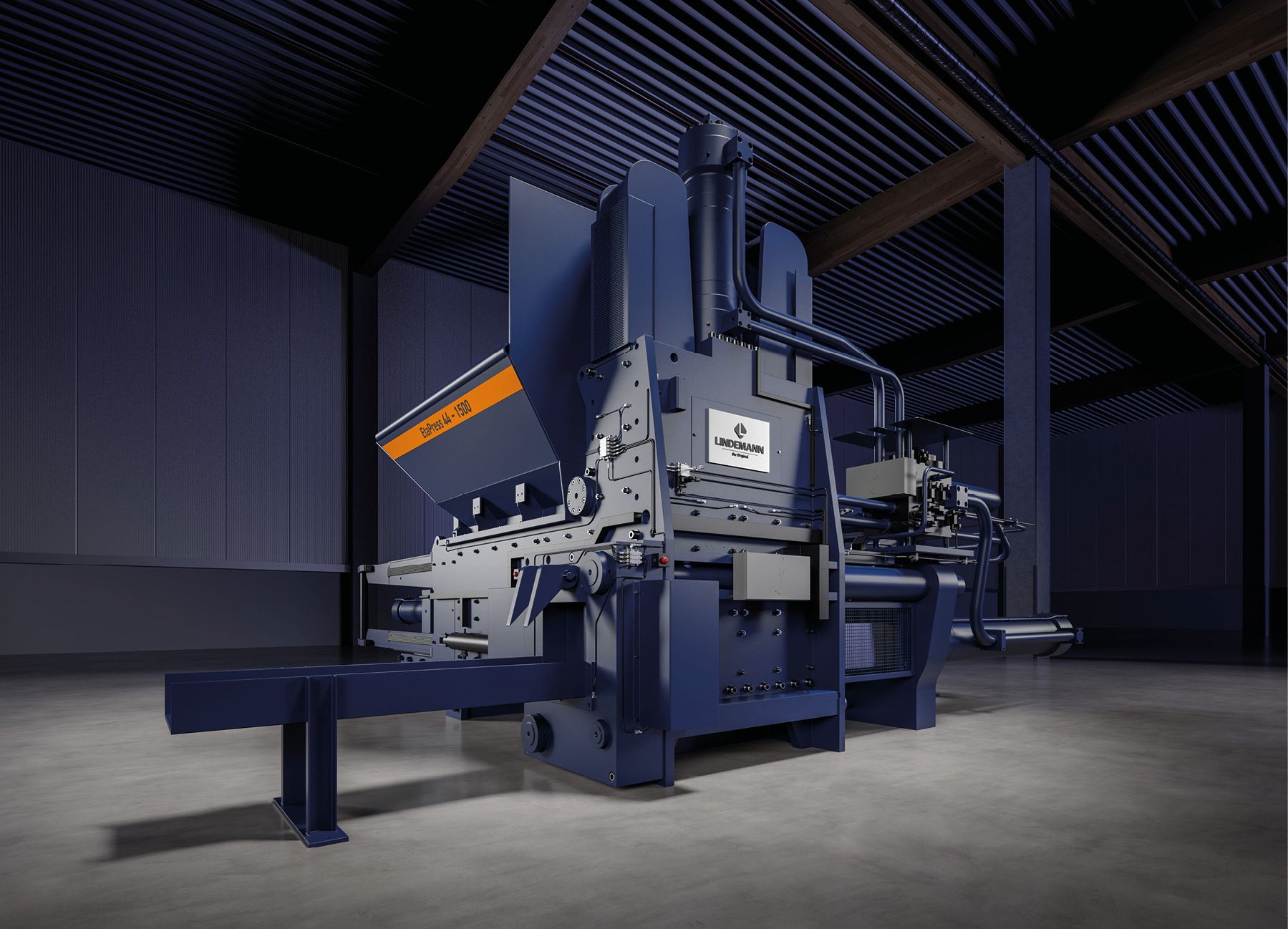

LINDEMANN EtaPress

Metal Baler

LINDEMANN EtaPress hydraulic metal baler is a scrap metal baler which operates with a three-sided compaction with a hydraulic operating pressure of up to 350 bars. The optimized construction of the compression chamber is made of smooth thick plates for the EtaPress 22 to 44 and the design of the compression units with their adjustable mechanical stops. They provide more stability and durability as well as operation safety under adverse operating conditions.

Metal baler field services

Metal baler training services

Metal baler performance services

Metal baler project and engineering services

Metal baler wear and spare parts