LINDEMANN EtaBriq Metal Briquetters

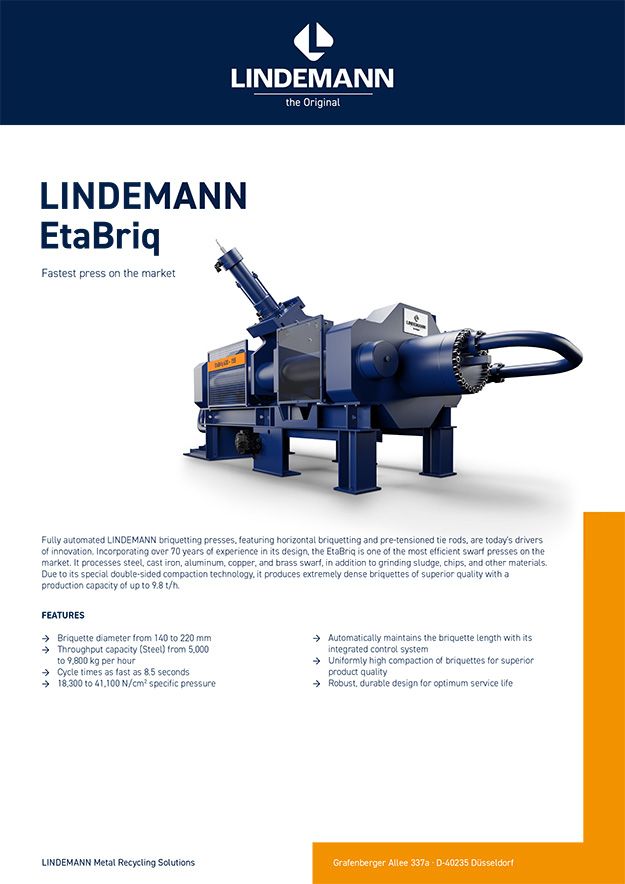

LINDEMANN EtaBriq briquetters are high-performance briquetting presses and fastest press on the market

Fully automated LINDEMANN briquetting presses, featuring horizontal briquetting and pre-tensioned tie rods, are today's drivers of innovation. They are designed to process large quantities of chips, both in the metal processing and the recycling industries. They are often used in processing steel, copper, aluminium and brass but can also be utilized when briquetting grinding sludge, mixed with chips.

Incorporating over 70 years of experience in its design, the EtaBriq is one of the most efficient swarf presses on the market. It processes steel, cast iron, aluminum, copper, and brass swarf, in addition to grinding sludge, chips, and other materials. Due to its special double-sided compaction technology, it produces extremely dense briquettes of superior quality with a production capacity of up to 9.8 t/h.

All features of the LINDEMANN product line for maximum durability, performance, efficiency and maintainability

In our data sheet you will find an overview of all features and technical data of the product line. This is available for you to download as a PDF file.

Lindemann Germany GmbH

Grafenberger Allee 337a

40235 Düsseldorf | Germany

Phone +49 211 2105 0