LINDEMANN NxtCut Scrap Metal Shear

LINDEMANN

NxtCut Scrap Metal Shear

Side compression Shear

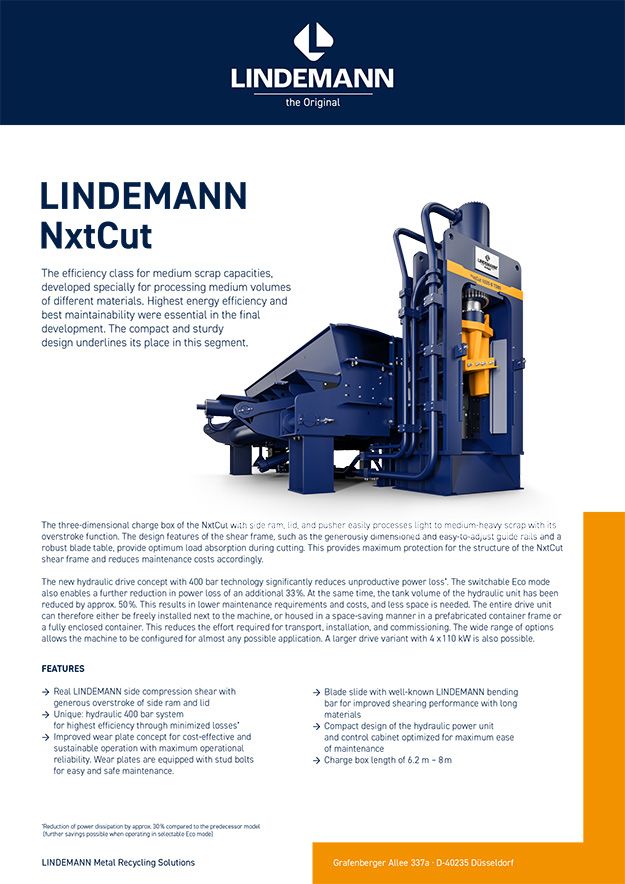

The efficiency class for medium scrap capacities, developed specially for processing medium volumes of different materials.

Highest energy efficiency and best maintainability were essential in the final development. The compact and sturdy design underlines its place in this segment.

Next generation of side compression midsize shears

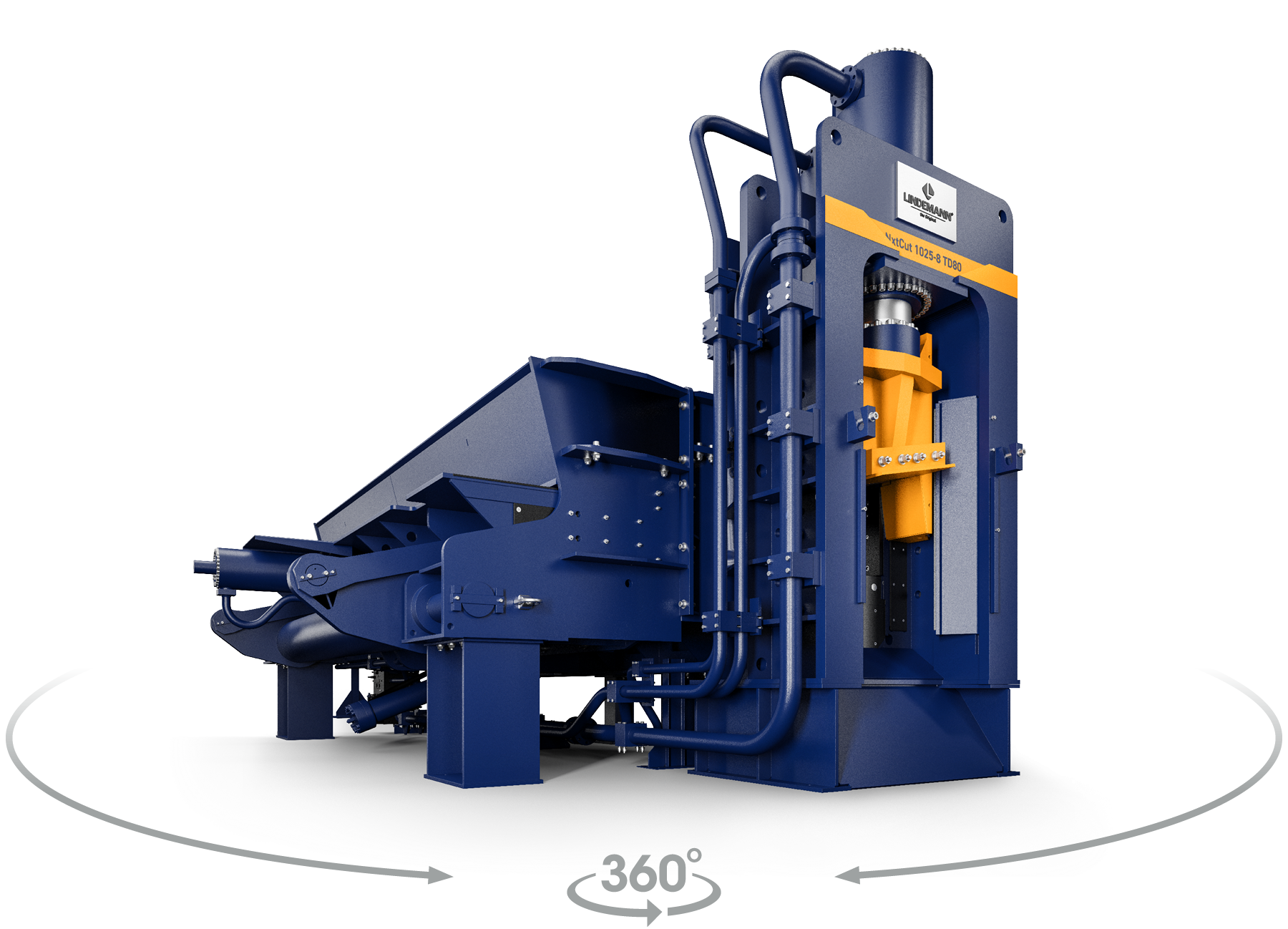

The three-dimensional charge box of the NxtCut with side ram, lid, and pusher easily processes light to medium-heavy scrap with its overstroke function. The design features of the shear frame, such as the generously dimensioned and easy-to-adjust guide rails and a robust blade table, provide optimum load absorption during cutting. This provides maximum protection for the structure of the NxtCut shear frame and reduces maintenance costs accordingly.

-

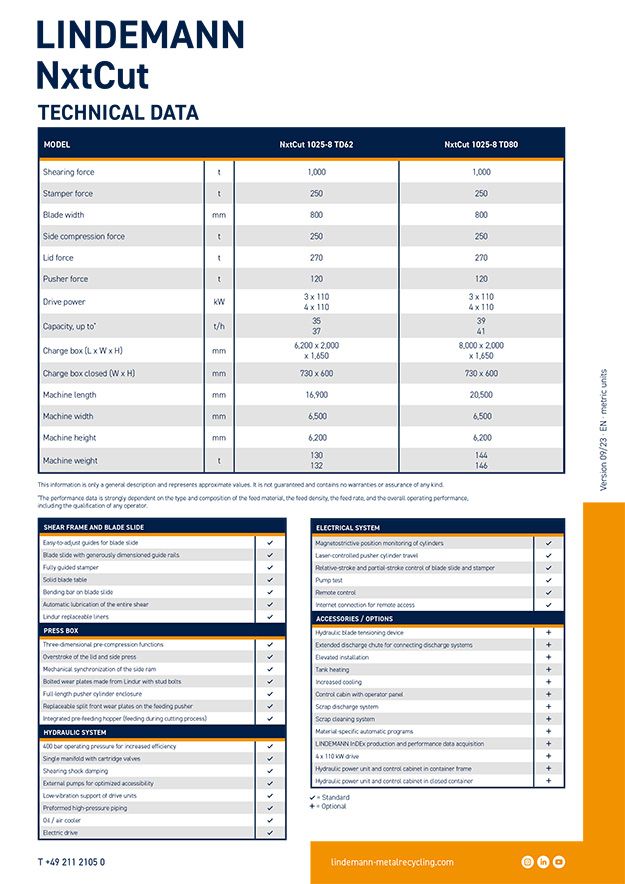

3 x 110 and 4 x 110 kW drive power

-

800 mm blade width

-

1,000 t shearing force

-

250 t stamper force

-

250 t side compression force

-

270 t lid force

-

120 t pusher force

-

Throughput/hour up to 41 t

-

Various accessories

The working Principle

Effective loading

The scrap is transported to the charge box by means of a grapple or crane. The material is compacted vertically by the lid in interaction with the lateral compaction by the side press. The generously designed overstroke of the lid and side press ensures maximum density and minimum wear in the box area. The laser-controlled pusher can additionally compact the scrap longitudinally if required. It then conveys it under the shear blade. The cutting and ejection process depends on the preselected cutting mode.

Powerful cutting

Mixed scrap that expands greatly after pre-compaction can be cut in „full stroke“ mode, while scrap that remains compact after pre-compaction can be cut in the time-saving „partial stroke“ mode. Any type of feed material with a constant fill level, such as bars and pipes, can be cut in „relative stroke“ mode to achieve the highest throughput rates for this material. The production of loose bales without any cut is realized with the „Logging“ mode.

New design of the hydraulic drive unit

- Efficient 400-bar hydraulic unit reduces the power losses in the system by more than 30%. This corresponds to a saving of 72,000 kWh (equivalent to 52 t CO2) compared with the predecessor model at the same annual output.

- The tank volume is reduced by 60% to 2,500 Liters.

- The reduction in the number of parts and components reduces maintenance costs and simplifies maintenance work.

Features

Future

Starts now

All features of the LINDEMANN product line for maximum durability, performance, efficiency and maintainability