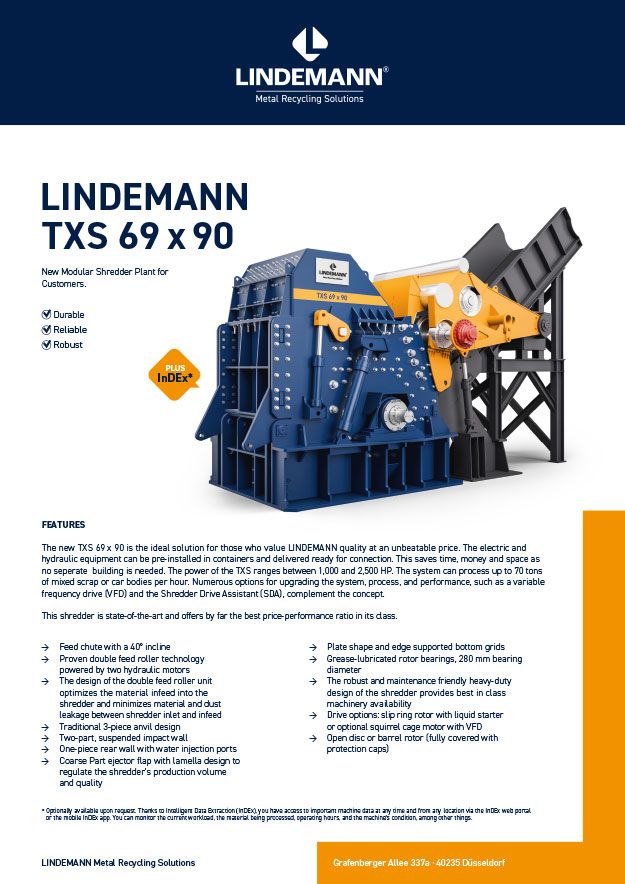

LINDEMANN TXS 69x90 Shredder LINDEMANN TXS 69x90 Shredder

New Modular Shredder Plant

Value Pricing and Premium Quality

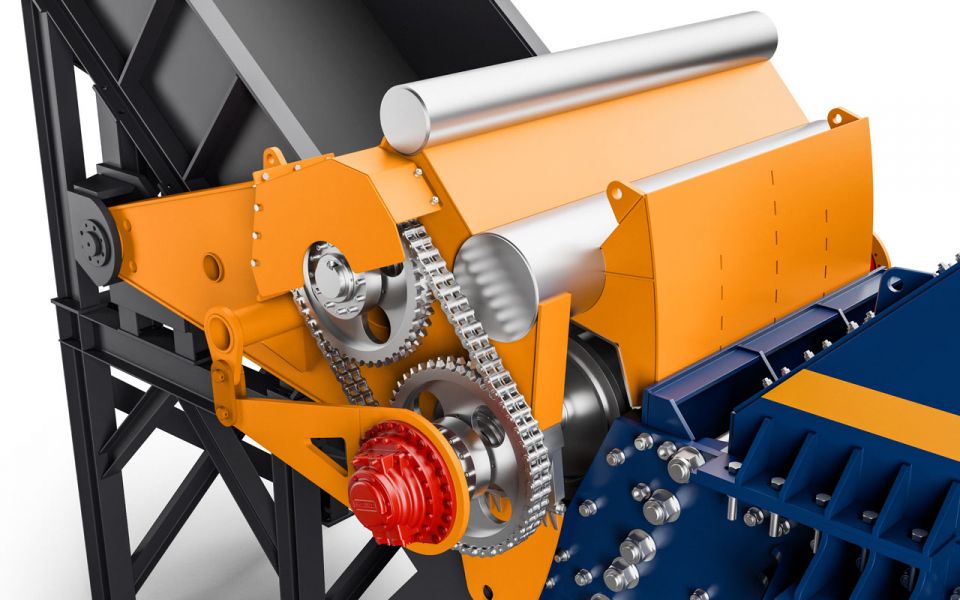

The new TXS 69x90 is the ideal solution for those who value LINDEMANN quality at an unbeatable price. The electric and hydraulic equipment can be pre-installed in containers and delivered ready for connection. This saves time, money and space as no seperate building is needed.

LINDEMANN mid-size Shredder: Durable. Reliable. Robust.

The power of the TXS ranges between 1,000 and 2,500 HP (735 to 1,840 kW). The system can process up to 70 tons

of mixed scrap or car bodies per hour. Numerous options for upgrading the system, process, and performance, such as a variable

frequency drive (VFD) and the Shredder Drive Assistant (SDA), complement the concept.

This shredder is state-of-the-art and offers by far the best price-performance ratio in its class.

-

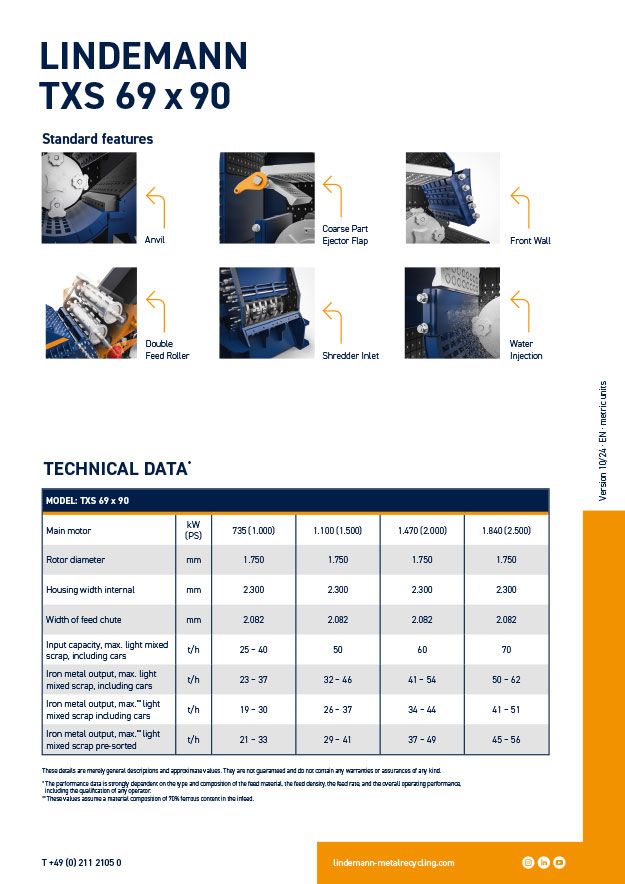

735 to 1,840 kW drive power

-

Throughput/hour up to 62 t

-

Available in four sizes

-

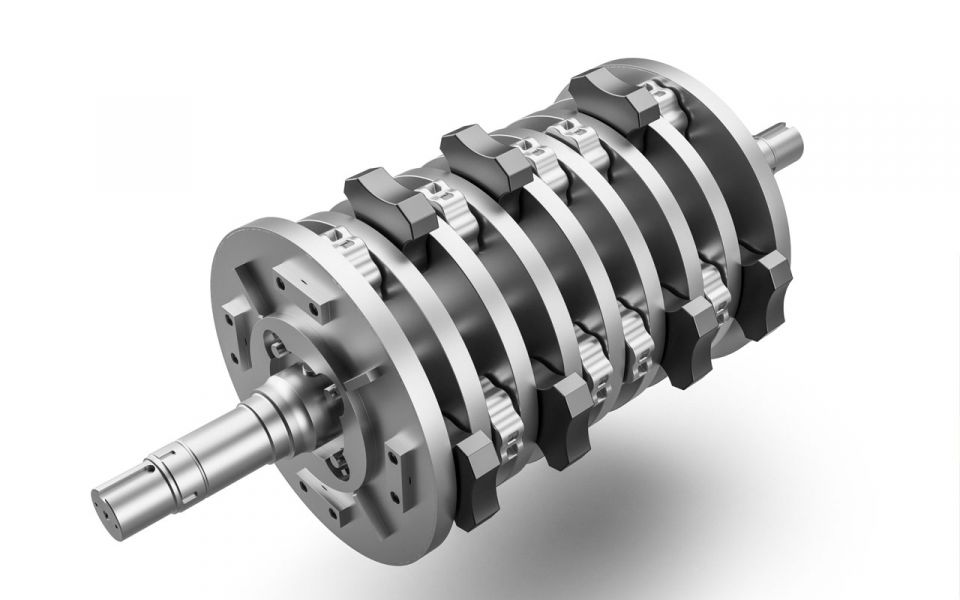

Rotor diameter of 1,750 mm

-

Internal housing width of 2,300 mm

-

Optional Shredder Drive Assistant (SDA) supports the feed process and optimizes throughput performance

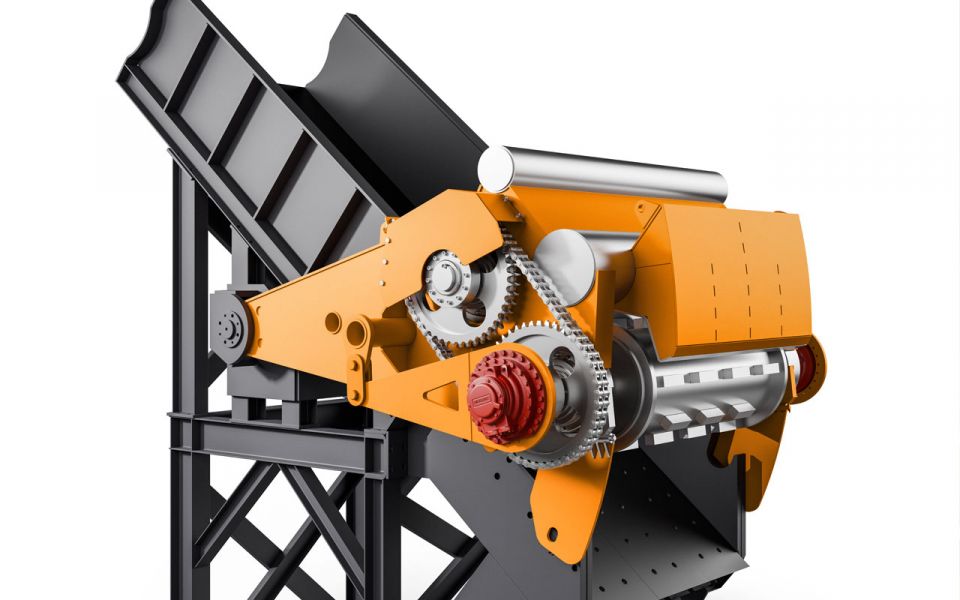

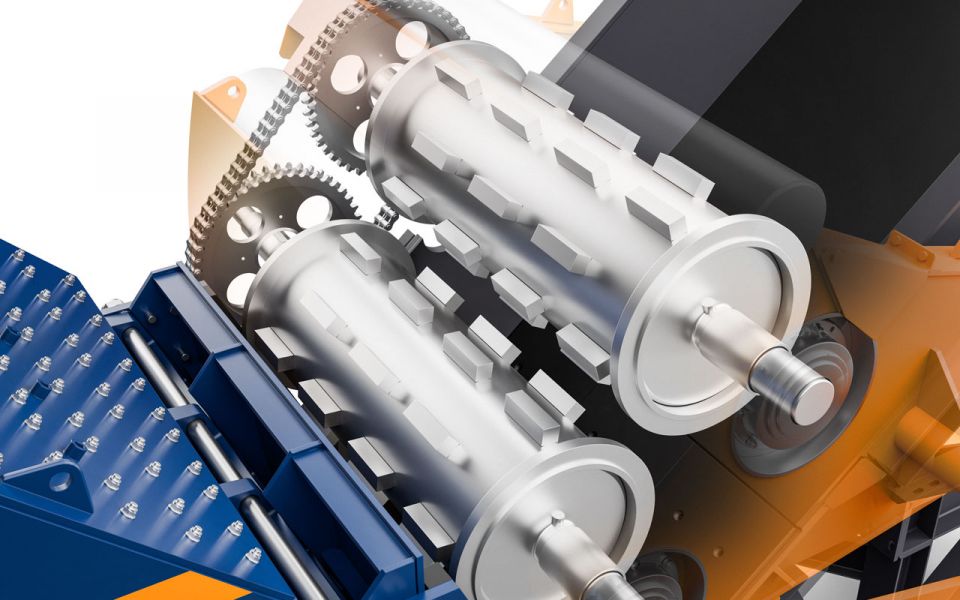

Features

Tough.

Xtra. Strong.

All features of the LINDEMANN product line for maximum durability, performance, efficiency and maintainability