YOU WINGS

LINDEMANN NxtCut WING

Scrap Metal Shear

LINDEMANN

NxtCut WING scrap Metal Shear

Scrap Shear with Press Wings

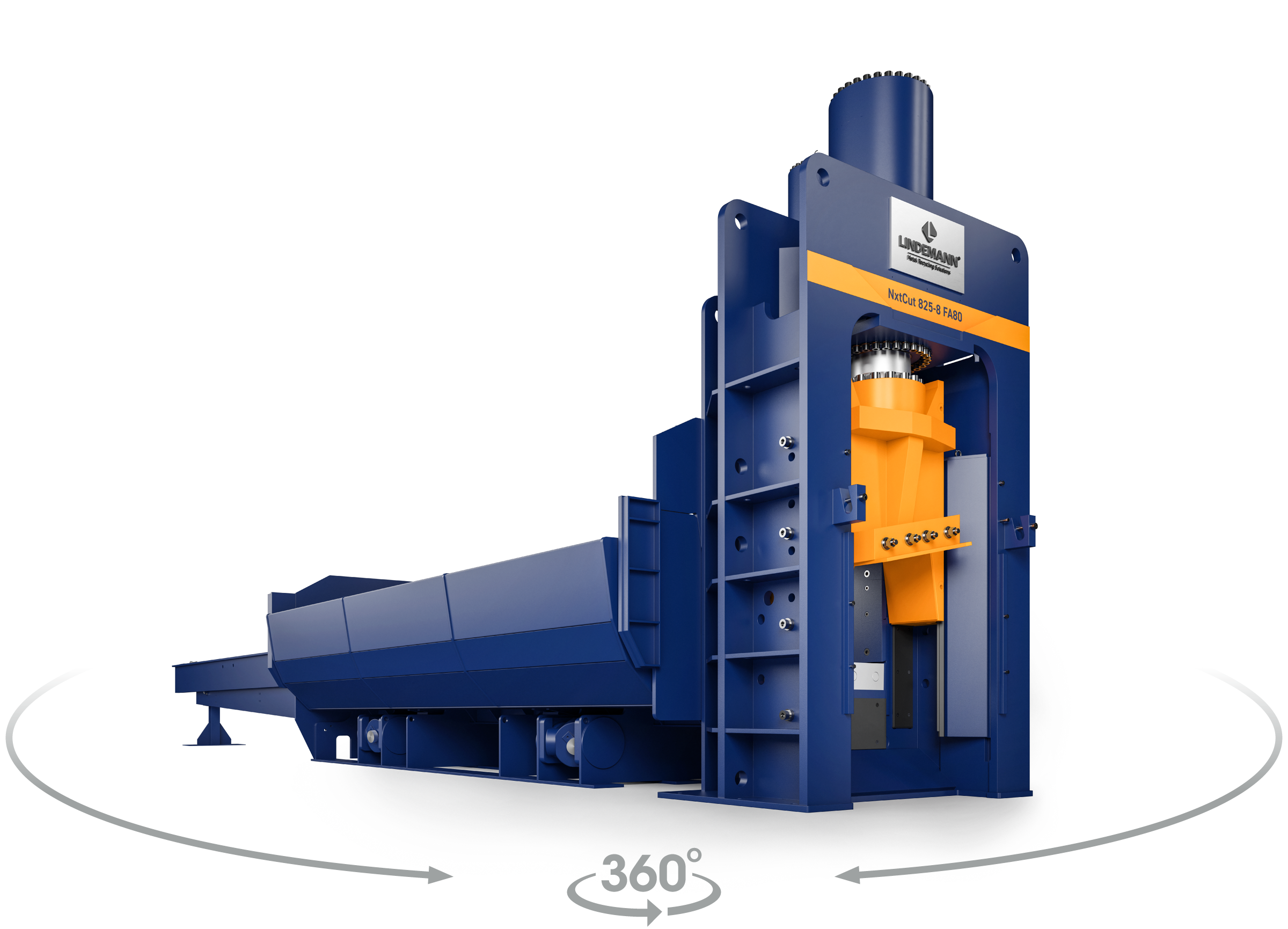

The NxtCut Wing is more than just an upgrade.

It’s a bold statement in efficiency, durability, and throughput. Equipped with a powerful wing-type compression box, it takes scrap processing to the next level.

New press wing shear with 400-bar technology

A separate hydraulic system with impressive 400-bar technology ensures consistently high performance. Smart sensors – including wear-free linear sensors in all cylinders and a protected laser sensor in the pusher cylinder – enable precise control, maximum operational safety, and minimal downtime. Low-wear guide components, a robust forged cutting table, and the press wings’ sophisticated overstroke mechanism help reduce wear effectively – even under high loads and fluctuating material flows. Selectable cutting modes adapt to different types of materials, enabling fast and clean cuts with short cycle times. The synchronized pusher cover protects sensitive components, while remote maintenance and Industry 4.0 connectivity via myLindemann provide full transparency and control – in real time and from anywhere. .

-

Press wing technology (14–38 t/h)

-

Bed lengths: 6.2 m or 8 m

-

Shear force: 800 or 1,000 t

-

Hydraulic system: 400 bar

-

Laser sensor in the pusher cylinder

-

Automatic cutting modes for various materials

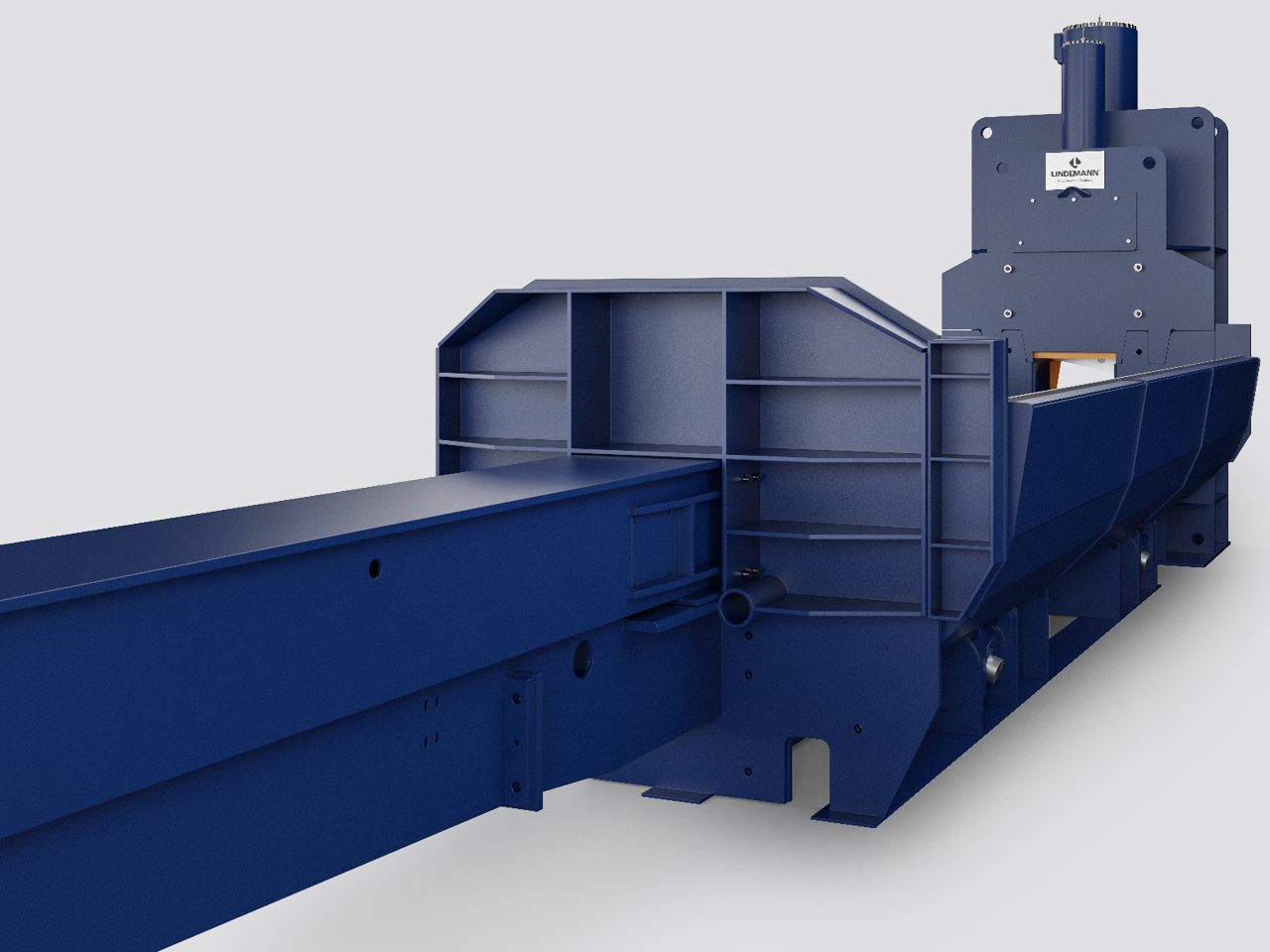

The Working Principle

Effective loading

Powerful cutting

400 bar hydraulic unit

Features

LINDEMANN

May Give

You Wings

Robust. Fast. Easy to Maintain.